GRC Façade Systems

Glass Fiber Reinforced Concrete is a lightweight and high strength composite used for architectural facades, cladding panels, decorative features, and complex exterior forms. Sana Al Jazira develops complete GRC systems through design, engineering, moulding, production, and installation to deliver durability, precision, and consistent performance across Saudi Arabia’s demanding climate.

Why GRC Façades Make Sense in the Gulf

Across Saudi Arabia and the wider Gulf, developers want façades that look bespoke—curved, perforated, deeply profiled—without loading the structure with heavy precast or stone. At the same time, consultants need systems that can be engineered, tested, and installed repeatedly on tight programmes.

Glass Fiber Reinforced Concrete (GRC, also called GFRC) answers this by combining a thin, 8–15 mm skin with glass fibre reinforcement and perimeter ribs, creating panels that are up to 70–75% lighter than traditional precast concrete while still having high flexural strength.  The lower weight cuts structural demand and simplifies lifting, especially on high-rise or overhanging geometry.

GRC also brings shape freedom. Spray or premix processes allow sharp lines, curves, and textures that are hard or uneconomical in stone or standard precast.  In hot climates, GRC panels can be designed as rainscreen or stud-framed systems that incorporate insulation behind the thin concrete skin, improving thermal performance without making the façade massive.

For owners, the result is simple: you get the visual impact of carved stone or precast, but at a fraction of the weight, with better control over joints, fixings, and long-term behaviour.

When GRC is the right choice:

When the structure cannot support the weight of stone or precast

When the design includes curves, deep profiles, or detailed patterns

When large facades require fast and efficient installation

When long term performance is required in hot and dusty areas

When value engineering is required without reducing architectural quality

What It Covers & Key Applications

What It Covers

Sana Al Jazira’s GRC façade offering covers the full system, not just loose panels:

- GRC panels and elements for podiums, towers, and public buildings.

- Domes, cornices, columns, balustrades, and decorative soffits.

- Parametric and non-repetitive panels, including double-curved surfaces.

- Stud-framed and bracket-supported systems with defined fixings and secondary steel interface.

- Integration with insulation, air–water barriers, and backing walls according to project requirements.

Key Applications

Large cladding systems on hospitality, cultural, and civic projects.

Complex podium façades combining solid GRC, perforated panels, and recessed glazing.

Underpasses, tunnels, parking structures and infrastructure where impact and durability matter.

Domes and minarets where weight reduction is critical for the supporting structure.

How Sana Al Jazira Delivers GRC Façade Systems

1

Concept & System

Selection

We review your elevations, sections, and performance requirements to confirm how GRC should be used—and where other systems (UHPC, GRP, metal) may be better. The goal is a rational system mix, not GRC everywhere by default.

2

Panelization &

Joint Strategy

Using 3D models and elevations, we define panel sizes, joint layouts, and movement breaks that work structurally, logistically, and aesthetically. This includes coordination with expansion joints, window modules, and access equipment.

3

Fixing Design &

Coordination

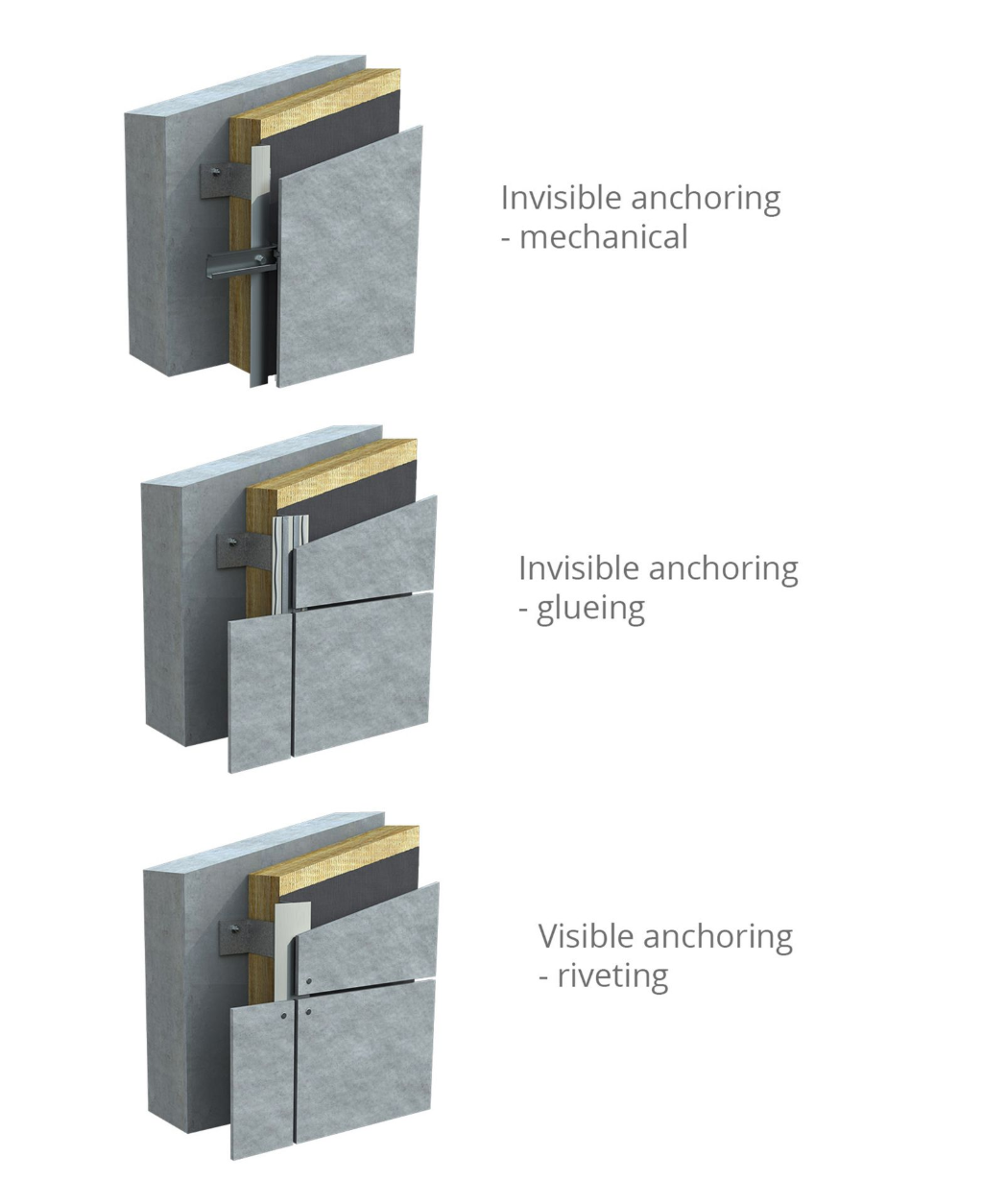

We design fixings—brackets, anchors, stud frames, rails—according to GRCA and project-specific guidance, allowing for three-way adjustability and movement between panels and structure. Stainless steel or appropriate corrosion-resistant fixings are specified for durability.

4

Mould Design

& Production

Mould types (timber, GRP, CNC-machined, or steel) are selected based on repetition and complexity. GRC mixing, spraying/premix, curing, and demoulding follow controlled procedures; typical skin thicknesses are 8–15 mm with ribs to provide stiffness.

5

Logistics, Installation

& Handover

We support the main contractor with lifting points, packing plans, and installation sequencing. On site, adjustment ranges in brackets and stud frames allow for real-world tolerances. At the end, as-built drawings, QA records, and maintenance recommendations are handed over.

Panelization Strategy: Getting GRC Joints Right

Joint layout is where GRC façades either look controlled and intentional, or chaotic and patched. The temptation is to chase the fewest possible joints, but that usually fights logistics, movement, and tolerances.

Good panelization starts from:

- Structural spans and support grid – panels should land on realistic fixing points, not imaginary lines.

- Access and handling limits – crane capacity, site hoists, and turning space often cap panel size well before strength does.

- Architectural rhythm – joints should reinforce the façade language, not cut randomly across key features.

For GRC especially, longer, thinner panels can deflect under their own weight or during lifting. Panels need sufficient ribs or intermediate fixings, and deflection limits should be agreed early. We align horizontal joints with slab edges where possible and keep vertical joints within a repeatable module, even on curved or inclined walls.

Movement joints are non-negotiable. GRC panels must be allowed to move relative to the structure: fixings provide vertical support and restraint, but slotted holes, sliding anchors, or flexible sealants absorb differential movement due to temperature and shrinkage.

Fixings, Frames, and Durability of GRC Systems

UHPC’s high strength tempts designers to create large monolithic panels, but logistics and risk management still matter. Panel sizes are governed not only by structural capacity but also by transport limits, crane reach, installation access, and damage risk. Large panels reduce joints but increase complexity if anything goes wrong; smaller panels increase joint count but make replacement and handling simpler.

At Sana Al Jazira we usually start from:

- Target panel sizes suited to available cranes and site conditions.

- Logical breaks aligned with architectural rhythms, windows, and movement joints.

- Back-side ribbing or thickened zones where fixings transfer loads.

Fixings for UHPC panels typically use stainless steel anchors, embedded plates, or cast-in channels coordinated with secondary steel. Anchor layout considers eccentricity, panel stiffness, and local stress concentrations. Using mock-ups and trial installations early in the project allows us to validate tolerances and fine-tune connection details before mass production.

For highly sculptural elements—curved fins, perforated screens, or deep reveals—we combine 3D modelling with digital mould fabrication so each element is tracked from model to mould to casting. That reduces re-work and ensures that what arrives on site actually matches the coordinated BIM geometry.

Projects Using GRC Façade Systems

GRC Façade Systems – FAQs

GRC uses a thin cementitious skin reinforced with alkali-resistant glass fibres instead of conventional rebar, typically 8–15 mm thick with ribs on the back. That makes panels much lighter—often up to seven times lighter than an equivalent 100 mm precast panel—while providing high flexural strength for thin-wall applications.

For façade cladding, skin thickness is usually 10–15 mm, with hollow ribs to provide stiffness and fixing zones. Panel sizes are then set by structural spans, handling limits, and access; we commonly work in the 1.0–1.5 m width range with lengths tuned to the project grid.

Properly designed and cured GRC performs well in hot climates and has been used for decades in the Middle East on façades, domes, and cladding without systemic durability problems. Its low thickness means it responds quickly to temperature changes, so detailing of joints and fixings is critical to accommodate movement and avoid cracking.

Yes. GRC itself is not a high-performance insulator, but stud-frame or rainscreen configurations allow mineral wool or other insulation to be placed behind the panel without increasing overall thickness significantly. This is standard practice on energy-conscious projects.

GRC is a non-combustible cement-based material. Fire performance of the overall façade depends on the full build-up—insulation type, membranes, subframe—but GRC itself contributes no fuel load. We coordinate with the project fire consultant to ensure details comply with the governing code.

With correct mix design, reinforcement, fixings, and maintenance, GRC façades can deliver multi-decade service life. GRCA guidance and long-term field performance from Europe, the Middle East, and elsewhere show GRC panels used successfully since the 1970s.

Minor chips and cracks can often be repaired in situ with compatible repair mortars and colour matching. For more serious damage, systems are designed so individual panels can be removed and swapped without dismantling large sections of façade, provided access is available.

Planning a GRC Façade or Decorative Envelope?

Bring us in while your elevations are still flexible. We’ll help you rationalise geometry, joints, and fixings so the GRC system is buildable, durable, and aligned with your structural and fire strategy—not something value-engineered at the last minute.