GRG Interior Solutions

Glass Reinforced Gypsum (GRG) ceilings, domes, and wall systems for high-end interiors where geometry, lighting integration, and surface quality are critical. Sana Al Jazira turns complex ceiling concepts into coordinated, buildable GRG packages.

Why GRG for High-End Interiors

Plain gypsum board is fine for flat ceilings. But once you introduce domes, coffers, deep bulkheads, complex curves, or integrated light coves, it quickly becomes a patchwork of framing, boarding, and jointing—with inconsistent surfaces and high labour risk.

Glass Reinforced Gypsum (GRG) is gypsum plaster reinforced with glass fibres, cast into thin, high-strength moulded units. Compared with traditional plasterwork, GRG offers a higher strength-to-weight ratio, crisper detail, and lighter elements, making it easier to suspend complex forms safely while reducing load on the primary structure.

For designers, GRG delivers:

- Freedom of form: domes, coffers, flowing bulkheads, and integrated light coves produced from precise moulds.

- Clean, repeatable surfaces: factory-cast elements reduce on-site plaster build-up and rework.

- Performance options: non-combustible gypsum with good acoustic and thermal properties, and the option for perforated or acoustic backings where required.

For owners and operators, GRG means interiors that look sharp, conceal services properly, and are easier to maintain over the life of the building.

What It Covers & Key Applications

What It Covers

Sana Al Jazira’s GRG scope typically includes:

- Feature ceilings and bulkheads with curves, drops, and integrated coves.

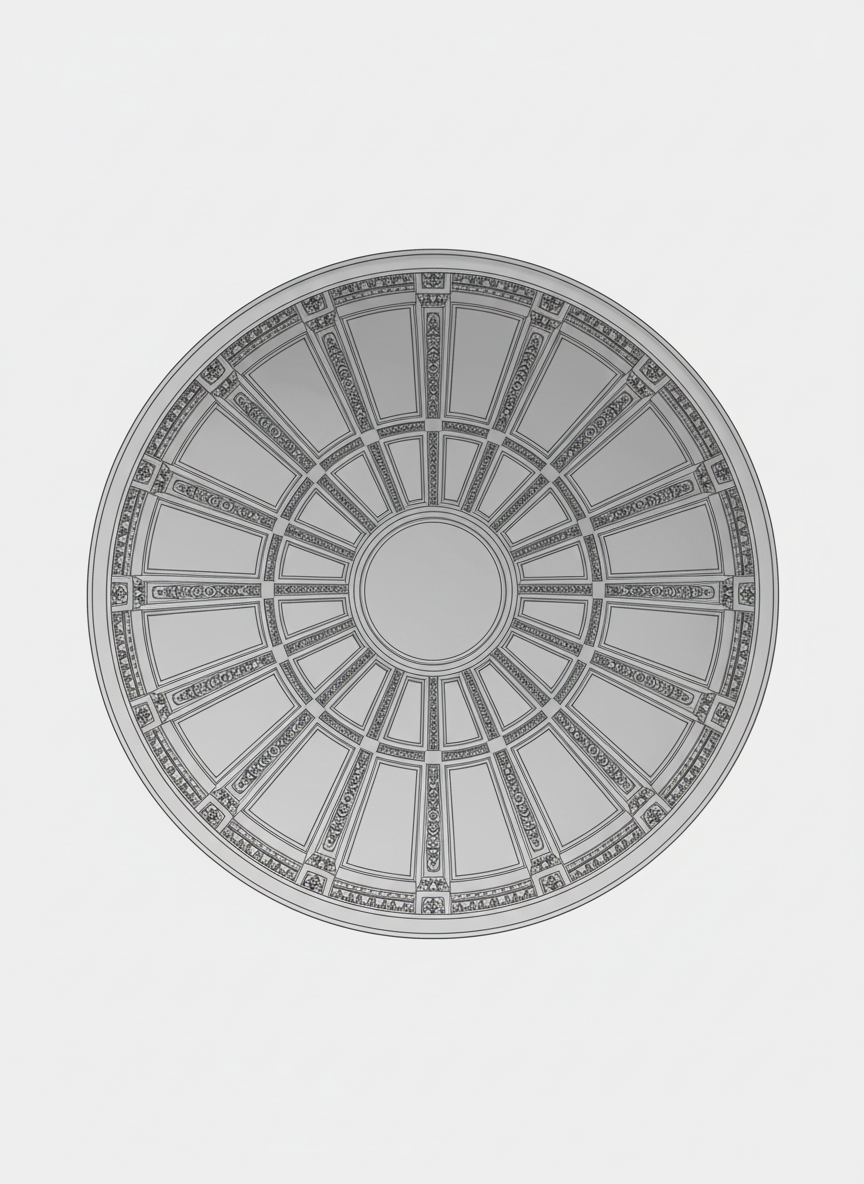

- Domes, coffers, vaulted ceilings, and decorative soffits.

- Interior columns, pilasters, wall panels, and mouldings in GRG.

- Perforated or acoustic GRG elements for improved sound control in key areas.

- Coordination of GRG with lighting, sprinklers, diffusers, speakers, access panels, and other ceiling services.

Key Applications

Hotel lobbies, ballrooms, corridors, and meeting floors.

Mosques, prayer halls, and religious buildings with domes and high ceilings.

VIP lounges, majlis spaces, palaces and high-spec residences.

Boardrooms, reception halls, and signature spaces in corporate HQs.

How Sana Al Jazira Delivers GRG Interior Solutions

1

Concept Review &

Ceiling Zoning

We start from interior design intent, reflected ceiling plans (RCPs), and MEP layouts, zoning ceilings by function: feature areas, service corridors, acoustic zones, and access areas.

2

3D Modelling &

Segment Breakdown

Complex forms—domes, coffers, flowing bulkheads—are modelled in 3D and broken into transportable GRG segments sized around access, lifts, and handling limits.

3

Coordination with

MEP & Lighting

We overlay sprinkler, diffuser, speaker, and lighting layouts onto the GRG geometry, resolving clashes and defining exact cut-outs, access hatches, and tolerances. Good RCPs and coordinated 3D models reduce rework and site improvisation.

4

Moulds, Casting &

Trial Assemblies

GRG moulds are fabricated (often CNC-driven) and used for repeated casting. Selected areas are trial-assembled in the factory to check joints, radii, and integration with framing before sending to site.

5

Site Installation

& Finishing

GRG units are fixed to metal framing or suspension systems sized for their light weight and stiffness. Joints are filled, sanded, and prepared as paint-ready surfaces that tie seamlessly into adjacent gypsum board or other finishes.

Coordinating GRG Ceilings with MEP & Lighting

The main technical risk in high-end ceilings is not the GRG itself; it is the clash between geometry and services. Ducts, sprinklers, diffusers, linear lights, speakers, cameras, and access panels all compete for the same ceiling space. Tight plenum depths—driven by developers wanting maximum clear height—leave very little tolerance for guesswork.

Best practice is to develop robust reflected ceiling plans and 3D coordination models early. GRG shapes are defined in the model; MEP services are then threaded through the available voids. Where services must pass through GRG, we fix locations and sizes for cut-outs and recesses—ideally down to specific fixture families—so moulds account for them.

For clients, this reduces:

- Late-stage redesign when a duct hits a bulkhead.

- Randomly shifted sprinklers and lights that ruin ceiling symmetry.

- Emergency access hatches hacked into finished work.

Sana Al Jazira’s advantage is that we think in system terms: GRG geometry, framing, and services are part of one coordinated package, not separate shop drawings that meet for the first time on site.

Segmenting GRG Ceilings for Installation & Maintenance

Visually, clients want uninterrupted curves and large coffers. Practically, GRG must be segmented for casting, transport, lifting, and future access. The trick is to hide the logic of those segments within the ceiling language.

Typical rules we apply:

- Follow natural breaks: coffers, ribs, cornices, and shadow gaps become joint lines.

- Limit segment size by lift dimensions, stair widths, and handling weight, not just structural strength.

- Build removable or hinged segments where future access to valves, dampers, or junction boxes is required.

GRG’s low weight—typically around 5–10 kg/m² for many interior units —allows relatively large pieces, but oversized units are harder to manoeuvre in finished interiors without damage. We find a sweet spot between visual continuity and sensible handling, and document it clearly in the shop drawings so all trades understand where joints actually lie.

Projects Using GRG Interior Solutions

GRG Interior Solutions – FAQs

Use GRG when you need three-dimensional forms, domes, coffers, deep bulkheads, or complex light coves, or when you want factory-cast quality. Flat ceilings with simple edges are usually more economical in board and framing; we’ll advise on the right split.

Plane sections are often in the 3–9 mm range, with local thickening and ribs for stiffness; weights commonly fall around 5–10 kg/m² depending on geometry. That makes GRG light enough for suspended systems yet robust enough to handle transport and installation.

GRG is best suited to dry or normal-humidity interiors; prolonged exposure to moisture is not recommended. In high-humidity or wet zones we either adapt the build-up or switch to more suitable materials and keep GRG for adjacent dry areas.

Gypsum is non-combustible and releases water when heated, which provides inherent fire resistance. GRG elements can form part of fire-rated assemblies when combined with appropriate framing, backing, and detailing according to the project’s fire strategy.

Yes. Perforated GRG systems with acoustic backing can significantly reduce reverberation, and are used in offices, auditoriums, and healthcare spaces. We can selectively combine decorative and acoustic zones in one ceiling language.

Access points are designed into the segmentation logic—either as demountable tiles, hinged sections, or discrete panels aligned with the ceiling pattern. We coordinate these with MEP to avoid surprises once the ceiling is closed.

Factory-cast GRG delivers crisp, consistent surfaces with minimal site finishing. Once joints are treated and sanded, GRG ceilings present a uniform, paint-ready surface far cleaner than traditional hand-built plasterwork.

Planning a Feature Ceiling, Dome or Bulkhead Package?

Send us your interior concepts and reflected ceiling plans. We’ll help translate them into a coordinated GRG scope that respects services, access, and long-term maintenance—not just the 3D render.